28 Mar Mudjacking vs. Polyjacking

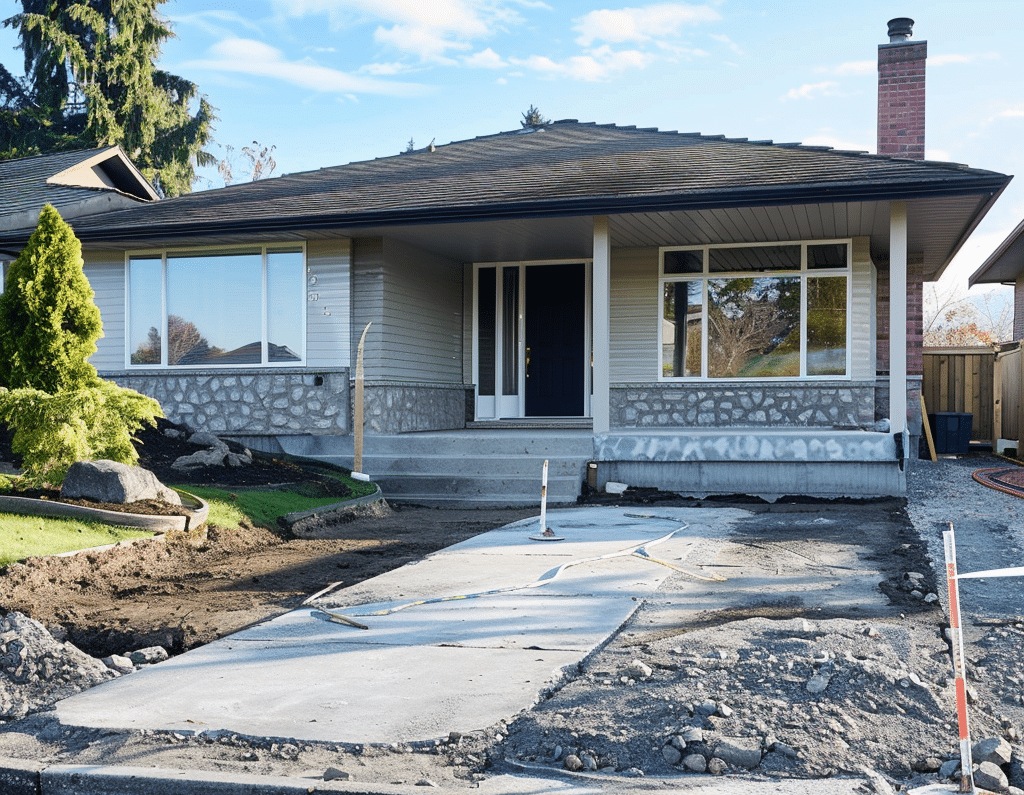

Uneven concrete slabs slope or stick out in an unappealing way. What’s more, they can endanger the people who might be passing that way. Imagine tripping over or stubbing your toe against one.

Because sunken or settled concrete slabs are unattractive and can also be harmful, it’s only natural for you to want to fix them right away. Replacement is costly, so you’re looking for an alternative.

You’ve heard about mudjacking and polyjacking, and both sound like good options.

Mudjacking and polyjacking are two common and effective ways to raise sunken or settled concrete. Both use a material which is injected underneath the uneven concrete slabs to push them up to the same level as the rest of the concrete through a process called concrete lifting.

Any of the two will make your patio, driveway or sidewalk attractive and safe again. But, which one should you choose? That depends on your needs and preferences.

The Differences Between Mudjacking vs. Polyjacking

Mudjacking is an old-school, tried and tested method of concrete leveling. It has been the go-to option for many contractors for more than 70 years, though its popularity has waned. On the other hand, polyjacking is a newer method which uses liquid foam. For this reason, it is also known as foam leveling, foam injection leveling, and polyurethane concrete raising.

Mudjacking is suitable for large repair jobs, i.e., those with more square footage. Meanwhile, polyjacking is better suited to smaller projects, thanks to its quick prep time and fewer crew requirements.

They also differ in many other ways, as listed below:

|

Mudjacking |

Polyjacking |

|

|

I. Installation |

||

|

Typically, 2 inches, but can range from 1.5 to 2.5 inches |

⅝ of an inch or roughly the size of a dime |

|

A mud slurry composed of soil, sand, water and cement Spreads out and fills more spaces and voids, resulting in a more solid and strong support |

A polyurethane foam Accumulates like a pancake; strength is focused on pancake pillars while other areas are prone to cracking |

|

Messier than polyjacking Prone to leakage that requires clean up |

Minimal mess The process can be clean and nearly dust free, but can leave difficult-to-remove stains |

|

Between 24 to 48 hours |

15 minutes |

|

II. Strength and Durability |

||

|

Mud slurry mixture can weigh 30 to 50 times heavier than poly foam |

Lightweight but strong |

|

Water permeable |

Waterproof |

|

Further compresses the soil underneath the concrete, causing it to sink and shift |

Compacts weak or unstable soils with no additional pressure |

|

III. Cost |

Less expensive than polyjacking |

More expensive than mudjacking |

Installation

Both techniques follow the same basic steps. Drill holes in the concrete, inject the material, and allow it to complete its curing time. Here’s where they differ:

- Drill hole size

When it comes to drill hole size, mudjacking has larger holes than polyjacking. The holes are typically 2 inches in diameter but can range in size from 1.5 to 2.5 inches, the largest among the concrete leveling methods. It needs these large holes so that the mud slurry can pass through freely.

Once cleaned, however, the holes might look like polka dots. Since the patched-up areas might not perfectly match the concrete, they’re hard to conceal and are unsightly. In addition, the large hole size might result in cracks on smaller slabs.

Meanwhile, polyjacking has the smallest holes among the concrete leveling techniques at just ⅝ of an inch or roughly the size of a dime. Since the holes are small, it’s less likely to cause a crack in the slab of concrete.

In addition, these small holes are less noticeable and can give the concrete a cleaner and more uniform appearance, especially since contractors only need a few holes to raise the concrete.

- Lifting compound or material

Mudjacking uses a mixture of four materials: soil, sand, water, and cement. When combined, they turn into a slurry which is like a not-so-sticky mud. Meanwhile, polyjacking uses a type of polyurethane foam similar to rigid styrofoam.

Though the mud slurry mixture is rough, it can fill more voids and spaces under the concrete slab compared to polyurethane foam. Once it hardens, the mud slurry can provide a strong and solid support.

On the other hand, foam injection behaves similar to shaving cream, which tends to accumulate in one area rather than spread out. This behavior of the polyurethane foam is known as pancaking. Injecting foam under a concrete slab is like stacking pancakes one on top of the other.

While it lifts the slab, the foam doesn’t fill all the spaces or void underneath. Strength or support is concentrated in the pancake stacks, but areas beyond those “pillars” are weak and prone to cracking under heavy weight.

- Clean up

Mudjacking is considered to be messier than polyjacking, in general. Mudjacking involves tons of slurry that might leak or spill. This will require a huge cleanup.

On the other hand, polyjacking typically involves minimal mess and the process can be clean and nearly dust free. However, in instances of foam leakage, it can leave stains that are difficult to remove.

- Cure time

Once the work is done, mudjacking requires between 24 and 48 hours of curing time. This means, concrete has to be left alone before it can be used again. Compared to polyjacking, it takes longer to cure.

For polyjacking, cure time can typically take just 15 minutes, so there’s basically little interruption. While this is great, the downside is that contractors have to be quick yet precise when doing the job.

Strength and Durability

If done properly, mudjacking can withstand heavy weight for several years. While different contractors have their own formula for mud slurry with various ratios and consistencies, it is generally considered to provide a strong repair. However, as the mud slurry can break down over time, the procedure needs to be repeated after two to five years.

Polyjacking, meanwhile, is lightweight but strong. Plus, it is also moisture resistant so it won’t be prone to breaking down. In other words, it can last indefinitely.

- Weight

While polyurethane foam is lightweight, mud slurry is 30 to 50 times heavier than poly foam.

- Moisture and water resistance

While mudjacking is perfect for areas that hold a lot of weight, such as driveways, it can be prone to water damage. The mud slurry mixture contains water and a lot of it. Once that water dries out, the remaining mud will shrink. It is also permeable to water, so it is prone to washing out.

Polyjacking, on the other hand, uses waterproof foam which will not shrink. But, while foam doesn’t erode, there’s no assurance that the soil underneath it won’t.

- Impact on soil stability

The heavy mud slurry can further compress the soil underneath the concrete, causing it to shift. The weighty mixture can only add to the burden of the already unstable soil and might cause the concrete to sink even further.

Polyjacking, on the other hand, uses foam so it is very light and compacts weak or unstable soils with no additional pressure.

Cost

Mudjacking costs, on average, a few dollars per square foot since the materials used for mud slurry are inexpensive. That is why it’s best suited for large jobs.

Polyjacking, meanwhile, is more expensive than mudjacking, averaging several dollars per square foot. The cost covers skilled labor, specialized equipment, and the mix of chemicals for the foam.

Deciding Between Mudjacking vs. Polyjacking

If you’re looking at a small job that requires precision and/or you want the holes as unnoticeable as possible, then pick polyjacking. If you’re facing a large job like a driveway or parking lot and/or you don’t mind the hole size, then schoose mudjacking.

But, no matter which one you pick, you’ll still save on replacement costs and that’s a win in our book.

No Comments